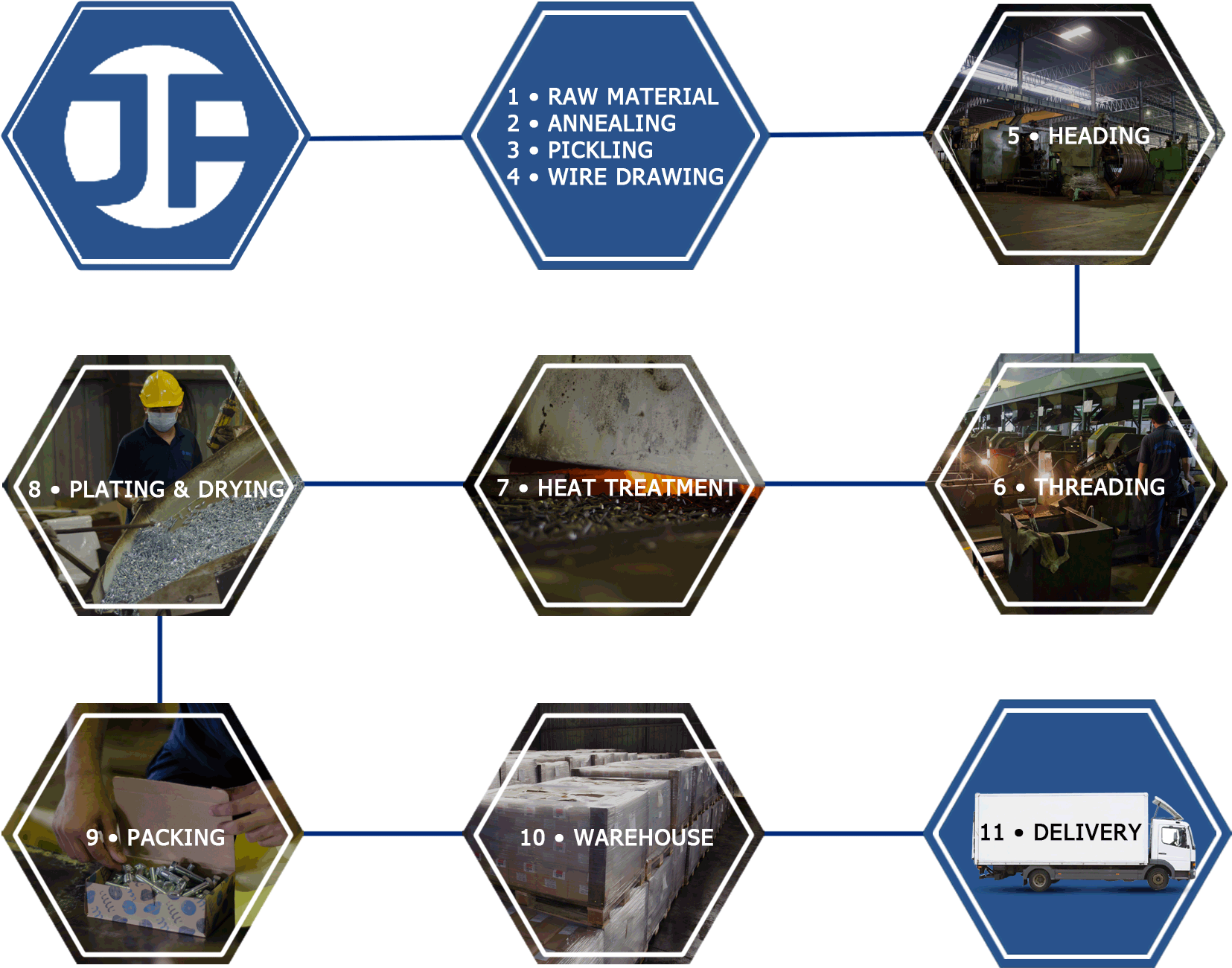

We undertake to maintain a high standard of quality in all our products in meeting all our customers’ requirements

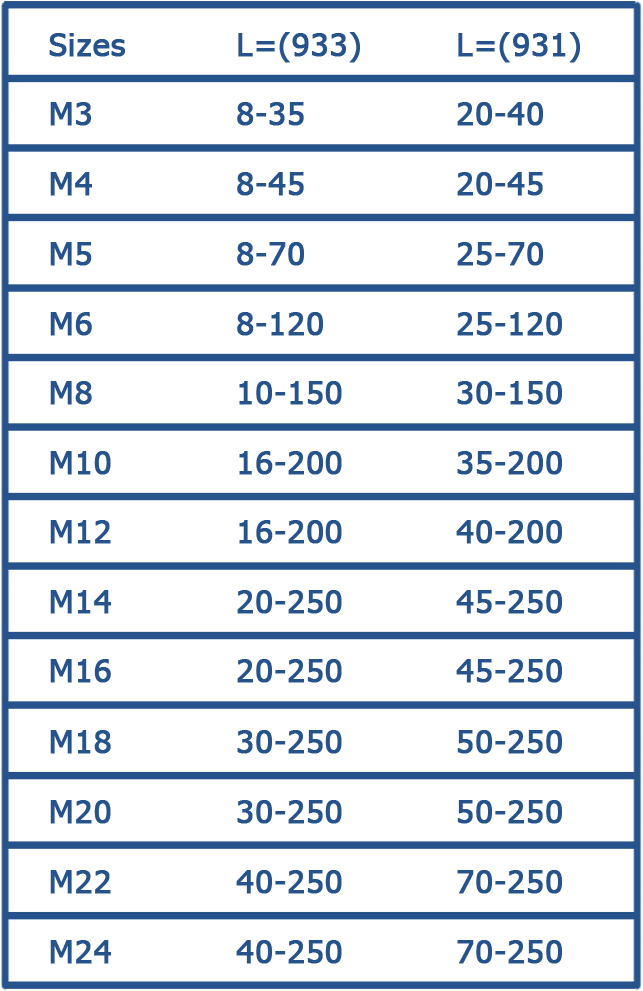

We understand that precision is very important in the process of bolts making and we put extra effort in offering the products that best suite your needs.

Any enquiries? We are here to help you.

Reach us by phone or email.